Product

Specializing in the production of conveyor belts, idlers, conveying machinery and accessories manufacturers

Hot products

ABOUT US

TAIDA Rubber Belt

A modern rubber conveyor belt manufacturing enterprise integrating R & D, production, sales and service

Baoding TAIDA Rubber Belt Manufacturing Co., Ltd. was established in 2013 and is located in Boye County, Baoding City, Hebei Province. It is a modern rubber conveyor belt manufacturing enterprise integrating R & D, production, sales and service. Since its establishment, the company has always adhered to technological innovation as the drive, product quality as the fundamental, and is committed to providing global customers with high quality, high-performance, high-reliability rubber conveyor belt and accessories products and solutions.

The company was established in

The monthly production capacity exceeds 200000 square meters, supporting the emergency delivery of bulk orders.

Sales country and region

CUSTOMIZED

OEM customization

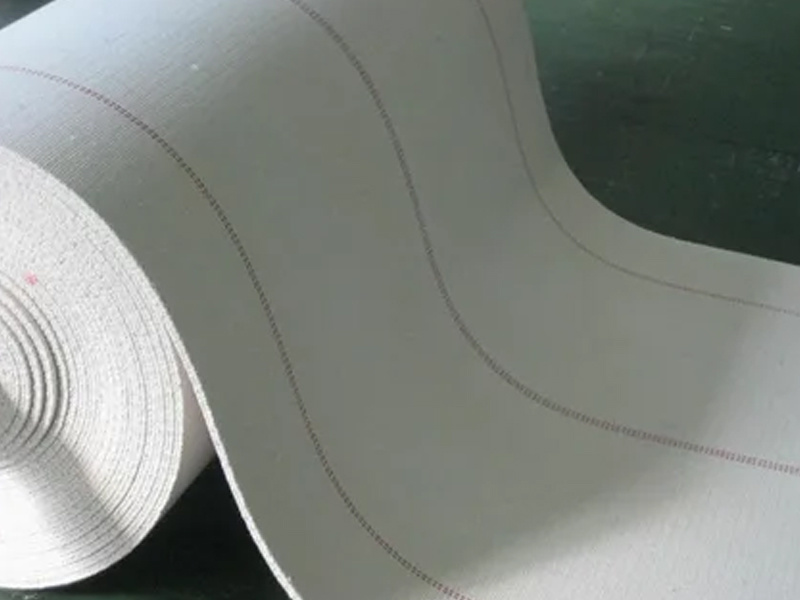

The company has an experienced technical research and development team, focusing on the research and development and application of new materials for rubber conveyor belts, and constantly introducing new products that meet market demand. The company has established long-term cooperative relations with many scientific research institutes to continuously improve the technical content and added value of products. The conveyor belt products produced by the company have excellent wear resistance, corrosion resistance, tear resistance and impact resistance, which can meet the needs of different industries and different working conditions.

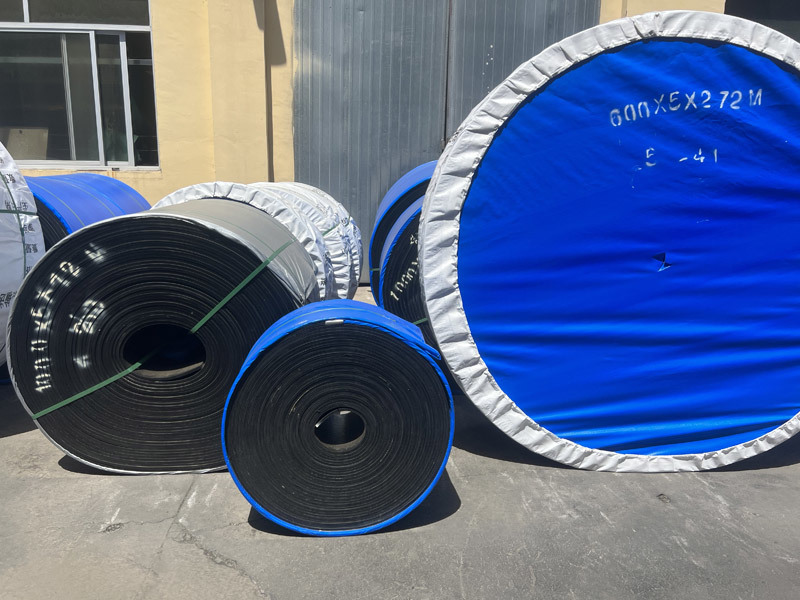

The company has a complete range of products, covering ordinary conveyor belts, heat-resistant conveyor belts, cold-resistant conveyor belts, oil-resistant conveyor belts, flame-retardant conveyor belts, steel wire rope core conveyor belts, special-shaped conveyor belts and other types of conveyor belts, as well as rollers, rollers and other conveying accessories, with complete specifications.

The company has a professional sales and technical service team, which can provide customers with timely and efficient technical support and after-sales service.

Conveyor belt products with special specifications and performance can be customized according to customer needs to provide customers with personalized solutions

Based in China, Global services

Established in2013years, service more20Other countries and regions

The company always adhere to the "customer first" service concept, the establishment of a sound pre-sale, sale, after-sales service system. The company has a professional sales and technical service team, which can provide customers with timely and efficient technical support and after-sales service, solve various problems encountered by customers in the use process, and ensure the smooth progress of customers' production.

Choose our advantage

Relying on independent research and development technology and fully automated production lines, we focus on the production of high-precision, wear-resistant special conveyor belts, strictly control the whole process of quality control. Provide customized solutions for mining, port, food and other industries, supporting 72-hour emergency delivery and global service network

Technical strength and production scale

The company has introduced a number of rubber belt production lines, and is equipped with advanced internal mixer, calender, vulcanizer and other production equipment, and is equipped with a professional physical performance testing laboratory, which can test the tensile strength, wear resistance, aging resistance and other key indicators of the product in an all-round way to ensure that the product meets national standards and customer requirements.

Quality assurance system

The company has a modern production base, covers an area of vast, equipped with domestic and foreign advanced production equipment and testing instruments. From raw materials into the factory to finished products, each process has undergone strict quality control to ensure stable and reliable product performance.

Scenario Solutions

Widely used in mining, ports, electric power, metallurgy, building materials, chemicals, machinery, food and other industries. In addition, the company can also customize special specifications and performance conveyor belt products according to customer needs to provide customers with personalized solutions.

Rapid Service Response

Telephone, mail, online customer service multi-channel access, technical team real-time answer load, bandwidth, material selection and other issues. Can receive small batch orders, 7-15 days delivery, support samples sent free of charge. Emergency orders can open up a green channel and ship at 72 hours (30% deposit required)

NEWS & BLOG

The working principle of a conveyor belt