Product Series

Contact Us

Telephone:

+86 13933091555

+86 13733368082

Whatsapp:

E-mail:

clairewang@bestconveyorbelt.net

Address:

North of Xiwanggezhuang Village, Boye County, Baoding City, Hebei Province

Cold-resistant conveyor belts are specifically developed for extreme low-temperature environments. They are made from a composite of special cold-resistant rubber and high-strength polyester canvas, maintaining excellent flexibility and wear resistance in extremely cold conditions, effectively preventing common issues like hardening, cracking, and breaking of ordinary conveyor belts at low temperatures. Its unique cold-resistant formula and precise manufacturing process ensure outstanding tear resistance and stable transmission efficiency. Coupled with high-precision vulcanization technology, the belt structure is compact and not prone to delamination. Furthermore, the product also possesses excellent chemical corrosion resistance and anti-aging properties, allowing it to adapt to various complex and harsh working conditions. It has a long service life, making it an ideal choice for material conveying in low-temperature operating scenarios.

OEMRefractory conveyor belts are special industrial conveyor belts developed for high-temperature operating environments. They feature a multi-layer composite structure design. The core layer is made of high-strength, heat-resistant fiber fabrics such as aramid fiber and ceramic fiber, providing excellent high-temperature resistance. They can operate stably for extended periods in extremely high-temperature environments, effectively resisting direct flame burning and high-temperature radiation. The surface layer is coated with special flame-retardant rubber or fire-retardant coating and undergoes professional flame-retardant treatment. When exposed to an open flame, it quickly forms a dense carbonized layer to prevent flame spread, meeting national flame-retardant standards. It also has good wear resistance and tear resistance, capable of withstanding friction and impact from sharp materials. The intermediate layer uses heat-insulating materials to further reduce heat conduction and protect the internal structure from high-temperature damage, ensuring the overall strength and stability of the conveyor belt. This product operates smoothly with high transmission efficiency and can adapt to the continuous conveying of various forms of materials, including powder, granular, and block materials. It is widely used in high-temperature industries such as metallurgy, power generation, casting, and glass manufacturing, providing reliable assurance for the safe and efficient transportation of high-temperature materials.

OEMHeat-resistant conveyor belts are specifically designed for high-temperature operating conditions and offer the following core features: they utilize special rubber covers to effectively resist high-temperature oxidation; they are equipped with enhanced skeletal structures to ensure high-strength conveying; special anti-stick surface treatment technology prevents adhesion of high-temperature materials; they possess dual safety protection features of flame retardancy and anti-static; they support various professional joint methods to ensure operational stability; their surface groove design enhances material carrying capacity; they operate smoothly with low noise, and are equipped with edge protection devices to extend service life. The product is widely applicable in high-temperature bulk material conveying scenarios such as metallurgical sintering, cement clinker, and chemical raw materials, significantly improving conveying efficiency and safety in high-temperature environments.

OEMHigh strength: Multiple layers of canvas provide good tensile strength and load-bearing capacity. Good wear resistance: The covering layer can be selected according to the different properties of the materials being conveyed to enhance wear resistance. Long service life: It has good anti-aging and weather resistance, extending its service life.

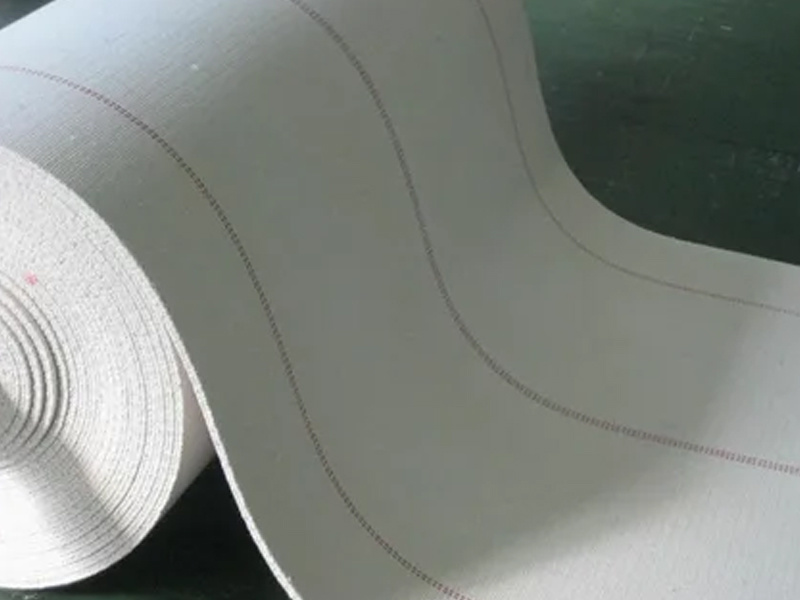

OEMCanvas core fabric conveyor belt

Coal and Mining Industry: Used for the medium and long-distance horizontal or inclined conveying of raw coal, limestone, coal ash, etc.Metallurgy and Chemical Industry: Used for conveying granular, blocky, and powdery materials such as coke, petroleum coke, phosphate rock, and aluminum hydroxide.Building Materials Industry: Used for long-distance conveying of materials such as cement, lime, gypsum, and sand.Grain Industry: Used for conveying materials such as millet, wheat, and soybean meal.Other Industries: Also commonly used in food factories, pharmaceutical factories, battery production lines, etc., in industries such as food, electronics, logistics, and steel.

OEMPlain canvas core fabric conveyor belt

Canvas conveyor belts are mainly constructed from pure cotton canvas, with both warp and weft woven from cotton fibers. They have low elongation and good adhesion. Some products may use warp-knitted blended fibers interwoven with weft cotton fibers, resulting in superior performance, thinner and lighter belts, and better impact resistance.

OEM