Product Series

Contact Us

Telephone:

+86 13933091555

+86 13733368082

Whatsapp:

E-mail:

clairewang@bestconveyorbelt.net

Address:

North of Xiwanggezhuang Village, Boye County, Baoding City, Hebei Province

Cold-resistant conveyor belts are specifically developed for extreme low-temperature environments. They are made from a composite of special cold-resistant rubber and high-strength polyester canvas, maintaining excellent flexibility and wear resistance in extremely cold conditions, effectively preventing common issues like hardening, cracking, and breaking of ordinary conveyor belts at low temperatures. Its unique cold-resistant formula and precise manufacturing process ensure outstanding tear resistance and stable transmission efficiency. Coupled with high-precision vulcanization technology, the belt structure is compact and not prone to delamination. Furthermore, the product also possesses excellent chemical corrosion resistance and anti-aging properties, allowing it to adapt to various complex and harsh working conditions. It has a long service life, making it an ideal choice for material conveying in low-temperature operating scenarios.

OEMRefractory conveyor belts are special industrial conveyor belts developed for high-temperature operating environments. They feature a multi-layer composite structure design. The core layer is made of high-strength, heat-resistant fiber fabrics such as aramid fiber and ceramic fiber, providing excellent high-temperature resistance. They can operate stably for extended periods in extremely high-temperature environments, effectively resisting direct flame burning and high-temperature radiation. The surface layer is coated with special flame-retardant rubber or fire-retardant coating and undergoes professional flame-retardant treatment. When exposed to an open flame, it quickly forms a dense carbonized layer to prevent flame spread, meeting national flame-retardant standards. It also has good wear resistance and tear resistance, capable of withstanding friction and impact from sharp materials. The intermediate layer uses heat-insulating materials to further reduce heat conduction and protect the internal structure from high-temperature damage, ensuring the overall strength and stability of the conveyor belt. This product operates smoothly with high transmission efficiency and can adapt to the continuous conveying of various forms of materials, including powder, granular, and block materials. It is widely used in high-temperature industries such as metallurgy, power generation, casting, and glass manufacturing, providing reliable assurance for the safe and efficient transportation of high-temperature materials.

OEMThe white rubber conveyor belt is made of high-quality, food-grade, non-toxic and harmless white rubber as the main raw material, combined with a special production process, and is specially designed for industries with extremely high cleanliness and safety requirements. Its core is made of high-strength polyester canvas or nylon canvas, and through a multi-layer bonding process, it gives the conveyor belt strong tensile strength, enabling it to stably carry various materials and is not prone to breakage or deformation.

OEMNylon conveyor belts use high-strength nylon fabric as the core, with a wear-resistant rubber surface, making them a superior choice for industrial material handling. They have high tensile strength, easily handling heavy materials such as coal and ore; they are wear-resistant and tear-resistant, resulting in a long service life and reduced equipment maintenance costs. They are resistant to acid and alkali corrosion, suitable for the chemical industry; and have a temperature resistance range of -10℃ to 80℃, with special models available for high temperatures. In addition, they have good flexibility, low running resistance, and are adaptable to small-diameter rollers. A wide range of specifications are available, with widths from 300-2000mm, and length, thickness, and width are all customizable. Parameters such as the covering rubber can also be adjusted. They are widely used in mining, ports, power generation, and many other fields.

OEMThe food machinery special conveyor belt's surface is specially treated, giving it excellent anti-stick properties. This effectively prevents food particles from adhering, avoiding spoilage and contamination of subsequent materials due to residual grain. At the same time, the conveyor belt has excellent wear and scratch resistance. Even when frequently conveying rice, wheat, and other grains with a certain degree of hardness and sharp edges, it maintains good integrity, reduces wear debris, and extends its service life.

OEMA circular conveyor belt is a conveying product where the two ends of the conveyor belt are joined into a closed loop through a special process, offering the structural advantage of a seamless, integrated design. This eliminates the hidden dangers of easy breakage and wear at the joints of traditional conveyor belts, significantly enhancing operational stability and service life. Its main body uses high-strength polyester canvas, nylon, canvas, or steel wire rope as the belt core, providing the product with excellent tensile performance to withstand material loads of various weight classes.

OEMCanvas core conveyor belts use high-quality canvas as the main core material. The canvas is woven from natural or synthetic fibers, and then multi-layered and laminated to form the belt core, which is then covered with wear-resistant rubber as a covering layer. Its structure gives the product good flexibility, allowing it to operate flexibly on smaller diameter rollers, reducing the demands on conveying equipment.

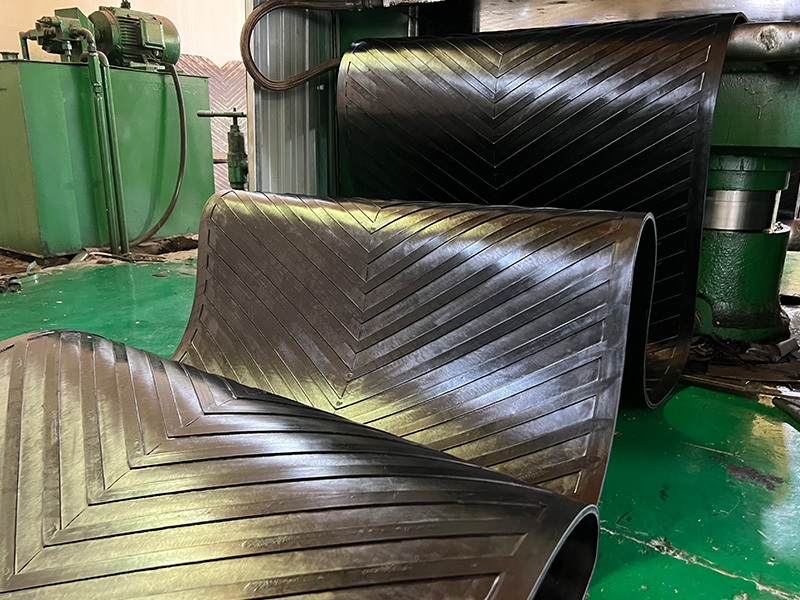

OEMSteeply inclined side conveyor belt

Steeply inclined sidewall conveyor belts are specialized conveying equipment designed to solve the problem of conveying materials at large angles. They consist of a base belt, a corrugated sidewall, and baffles. The unique structural design allows for vertical or steeply inclined lifting and conveying of materials within a 0-90 degree range, effectively saving space and optimizing production line layout. The base belt uses high-strength polyester canvas or steel wire rope core, with excellent tensile strength and tear resistance; the corrugated sidewall and baffles use high-quality rubber material, which is flexible, wear-resistant, and aging-resistant, preventing material slippage and spillage during conveying. This conveyor belt has high conveying efficiency and can adapt to the continuous conveying of various forms of materials such as powder, granular, and block materials. It is widely used in mining, ports, chemical industry, grain and other industries, significantly improving material transportation efficiency in complex working conditions.

OEMRecessed pattern conveyor belt

A typical conveyor belt consists of a belt, rollers, a drive mechanism, a tensioning device, and a support structure. The belt carries items and transmits power, the rollers provide support, the drive mechanism drives the conveyor belt, the tensioning device maintains the proper tension of the belt, and the support structure provides a stable base.

OEMRecessed pattern conveyor belt

A typical conveyor belt consists of a belt, rollers, a drive mechanism, a tensioning device, and a support structure. The belt carries items and transmits power, the rollers provide support, the drive mechanism drives the conveyor belt, the tensioning device maintains the proper tension of the belt, and the support structure provides a stable base.

OEM